Vancouver's Rubber Paving Experts

Thanks to its slip-resistant and impact-resistant properties, poured-in-place rubber surfacing is the most popular playground surface choice for city parks, daycares, and school playgrounds in BC.

The thicker the product, the safer it is. Poured-in-place rubber surfacing provides a safe surface for kids to play on, as the base-layer thickness (1/2″-5″) and the wear-layer thickness (usually 1/2″) can easily be controlled to ensure that the surface meets Canadian Drop Fall requirements.

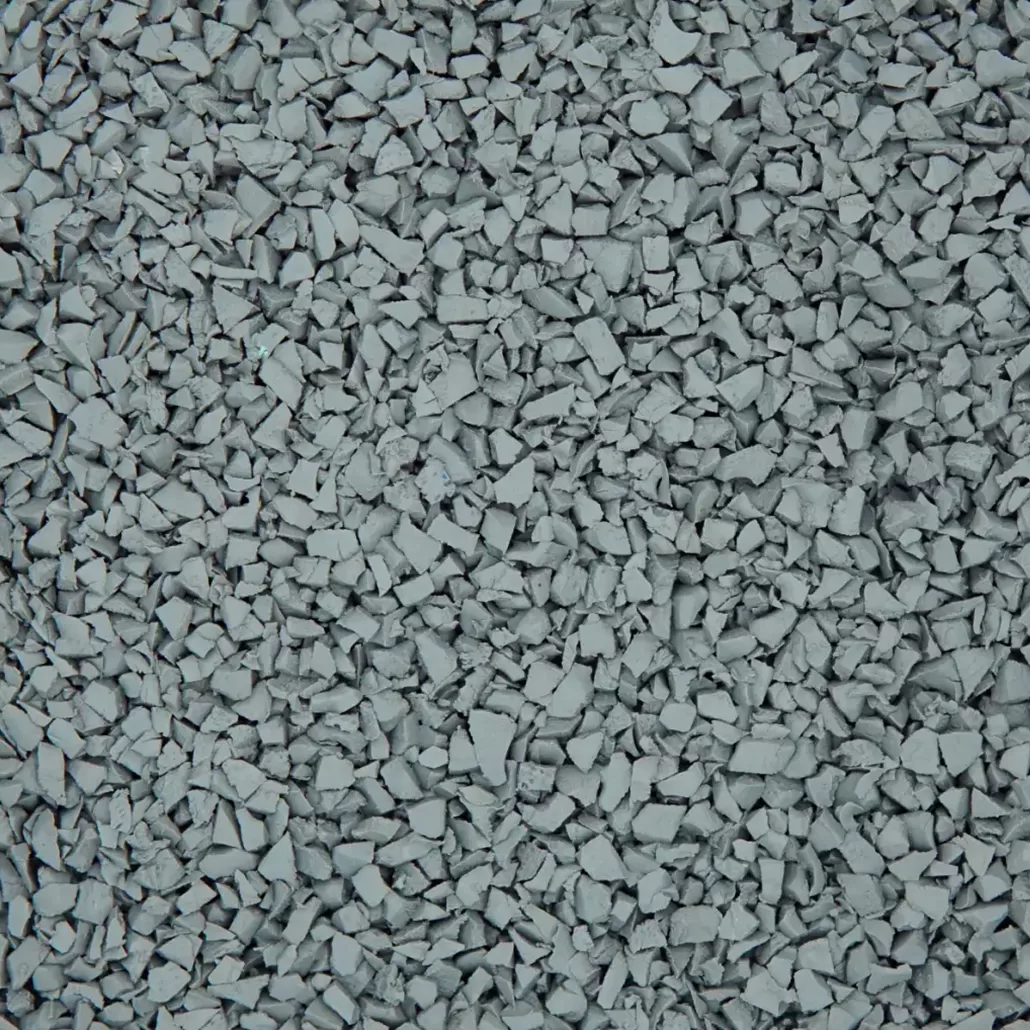

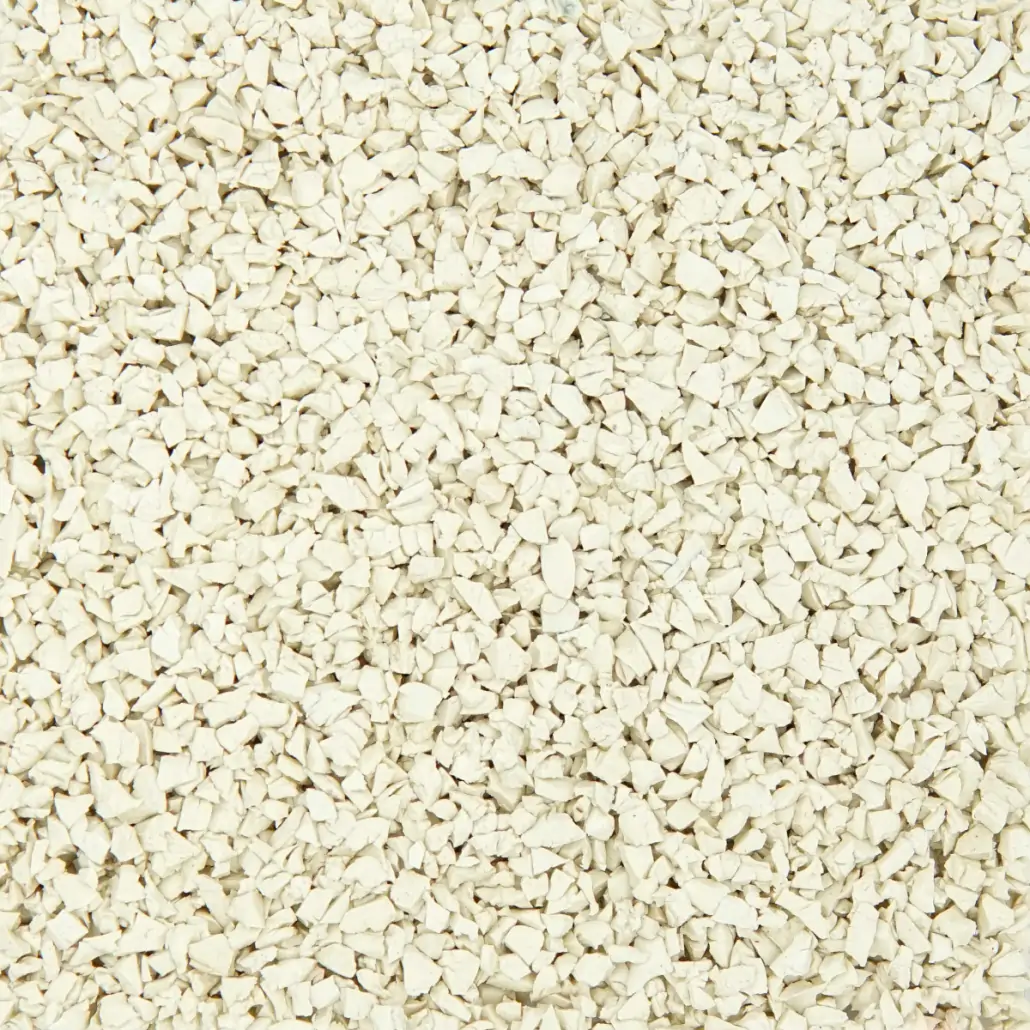

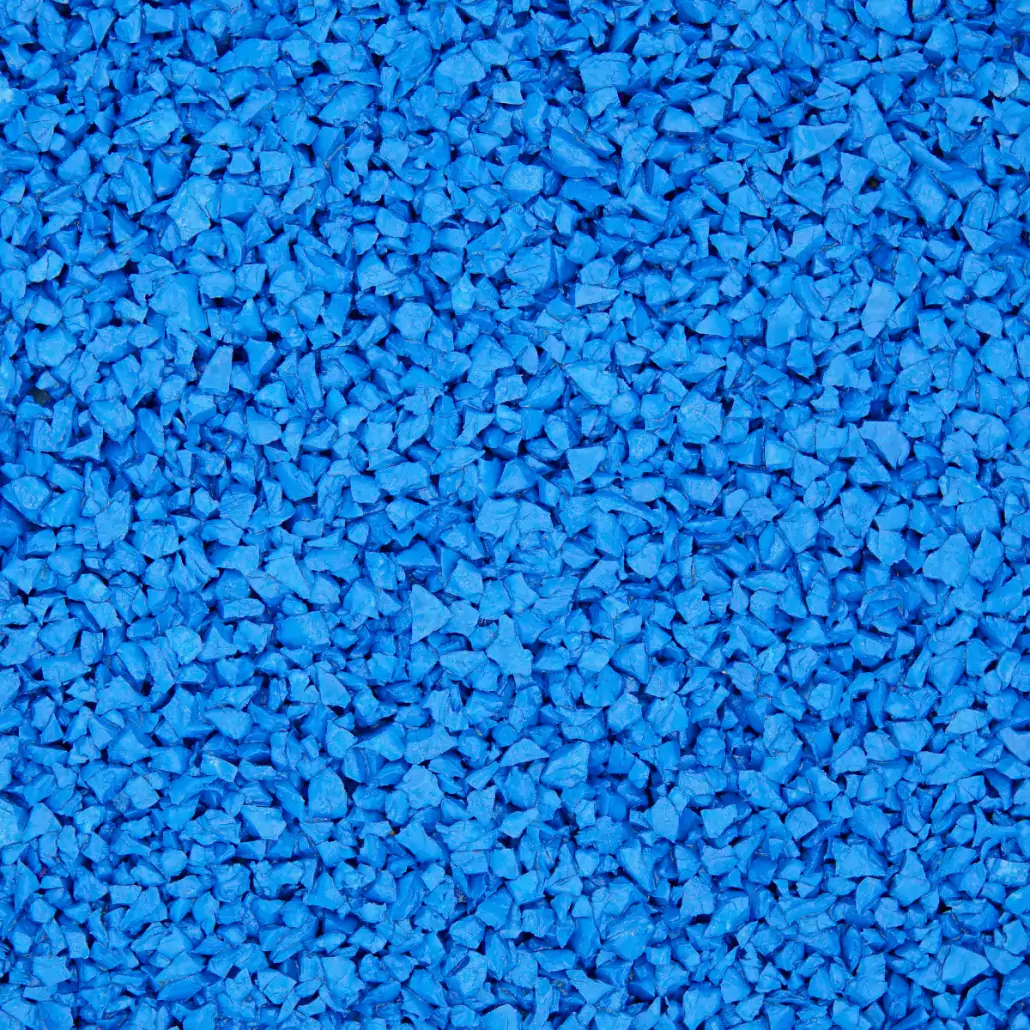

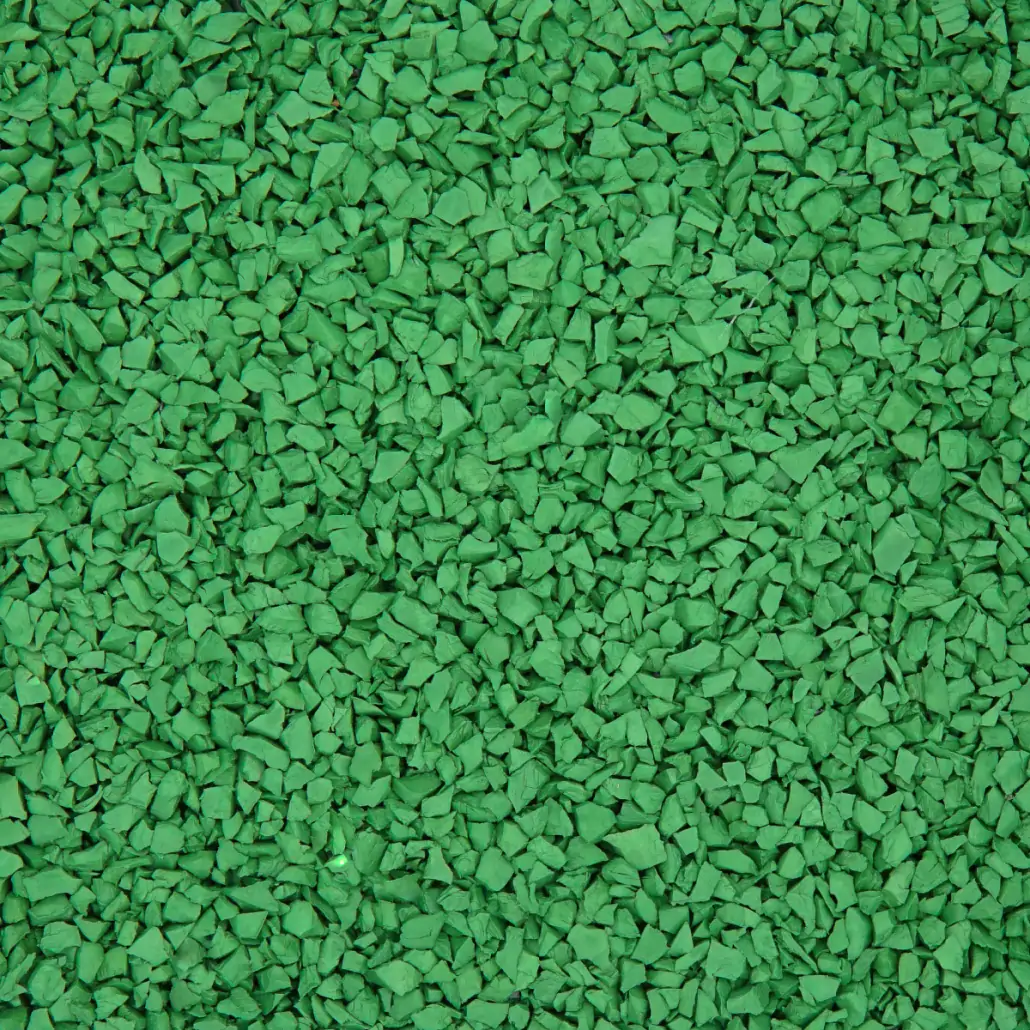

The base layer is made using a blend of SBR rubber and a base layer binder. Once the base layer has set and cured, the wear layer is placed on top of the base layer. The wear layer can be done in black, single colours, colour blends, or unique designs. The poured-in-place system can be as small or as large as you want, and features a semi-porous surface that allows water to flow through to the lower substrate. Once cured, the rubber surface will stay in place and will last for many years to come.

Any of the available colour options can be mixed in combination with another colour or mixture of colours to achieve a blended and speckled look; however, a percentage of black SBR is mixed into the colour or multiple colours to help camouflage dirt. It is also important to keep in mind that the higher percentage of black in the wear layer mix, the lower the price will be.

As a moisture cure, single-component polyurethane binder, VSS Aromatic Polyurethane is designed for a range of different applications, such as driveways, walkways, pathways, torch on decks, vinyl decks, patios, and playgrounds. While this product is very durable, it is best applied to black or mostly black poured-in-place surfacing, as it will amber or create a yellowish look within the first 24 hours of the application; however, it is important to note that the ambering or yellowing effect will disappear over time. The VSS SL-Series is based on premium-quality diphenylmethane diisocyanate (MDI) prepolymer.

Designed for patios, and walkways, our premium-quality VSS Aliphatic Polyurethane prepolymer is a moisture cure, single-component polyurethane binder that is excellent for UV stability and can be used with any colours of SBR and EPDM that we offer. This product is extremely strong and will not amber or have the yellowish effects as seen in the aromatic binder. As it is a premium product, the cost per square foot is more expensive than the aromatic.

Vancouver Safety Surfacing provides comprehensive rubber paving services for driveways, garage floors, patios, decks, playgrounds, daycares, and commercial projects. Our rubber resurfacing products are environmentally friendly and are uniquely designed to make the surfaces you walk on safer.

Copyright © 2024 Vancouver Safety Surfacing. All Rights Reserved. Privacy Policy

Website by Vancouver Safety Surfacing